Made in Germany

Transparent and sustainable production conditions have become an important purchase criterion for increasing numbers of customers. What exactly "Made in Germany" means, however, is a matter of debate, as the term is not clearly defined.

We’d like to show you how and where we produce, and why our products really do merit the "Made in Germany" seal of approval.

From raw material to fitted sheet

Step 1: Cotton… a fantastic raw material

The majority of our products are made from cotton. Cotton is a wonderful raw material, but unfortunately it doesn’t grow in Germany. We source our high-quality single and ply cotton yarns, and our ultrafine elastane thread from a small circle of German yarn dealers. The cotton is grown mainly in India and the United States, while the processing of cotton into a single or ply yarn mostly takes place in India or Turkey.

Our single and ply yarns are delivered to us wrapped on large rolls or cones. They come in their original colour: a natural white.

Our elastane threads come from Asia and are also produced in accordance with STANDARD 100 by OEKO-TEX®.

What defines our quality in this step:

- Length of cotton fibres: We use especially long to medium length fibres. The longer the cotton fibre, the better the quality.

- Combed cotton: this removes any remnants of husk and other contaminants, and realigns the fibres.

- Ply cotton yarn: particularly fine and even single cotton yarn is produced and twisted together to create a robust and hardwearing ply yarn.

- Compact yarn: unlike conventional yarn, here the fibre ends are compacted into the yarn. This prevents break points in the thread and results in a smooth surface that prevents balls developing, otherwise known as pilling.

- Gassing: also known as singeing, this step removes any protruding filaments using a flame, making the yarn more uniform and removing the last protruding fibre ends so as to prevent pilling.

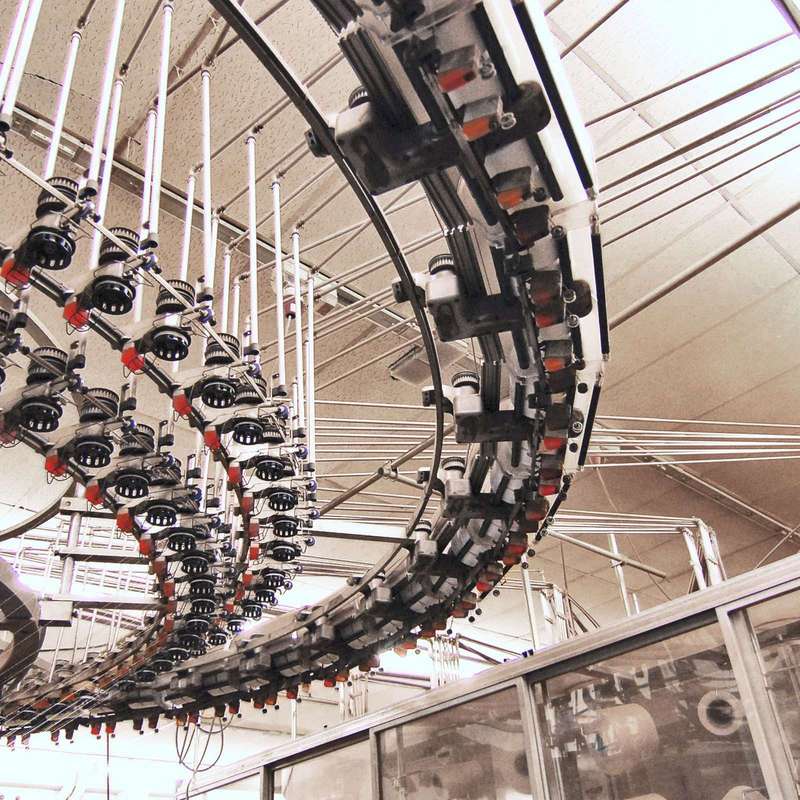

Step 2: Our fabrics are knitted

Our single and ply cotton yarns are all knitted in Germany – in the same knitting rooms as they have been for decades. Hundreds of cones of yarn are attached to a knitting machine and thousands of knitting needles work in unison. As part of the process, single or ply cotton yarn is combined with an ultrafine elastane thread and knitted together to create an elastic jersey fabric. The elastane thread is so fine that the proportion of elastane makes up no more than 4% of the fabric!

The outstanding elasticity of our products – the perfect interplay of stretchiness and elastic recovery – is why our fitted sheets give you such a perfect, crease-free fit. This elasticity is created by carefully combining cotton and elastane in the knitting process (also known as elastomeric plating) and by a high-quality knit with a particularly large number of very fine stitches.

What defines our quality in this step:

- Modern knitting production in Germany

- Very small and fine knitted stitches

- Addition of ultrafine, extremely elastic, tear-resistant, elastane threads

Step 3: Dyeing and finishing our fabrics

Our next step is dyeing and finishing our fabrics here in Germany. We continually improve our modern facilities to guarantee the high quality of our products, and also to ensure that our production process is a sustainable and environmentally friendly one.

The finishing of our fabrics is a highly complex process, because we want to retain their special softness, their uniform, close-meshed surface and elasticity despite washing, bleaching, dyeing, drying, etc. Our fabrics undergo a specially developed textile finishing process. The tubular fabric is finished very gently before being cut. A typical feature of this finishing process is the centrefold or pleat mark: a fine crease that runs down the centre of our sheets and that gradually disappears when you begin using the sheet.

Our sustainable textile finishing conditions:

- Implementing the European Chemicals Regulation REACH

- Quality is produced and certified according to STANDARD 100 by OEKO-TEX®

- Our production site is certified in accordance with ISO 9001

What defines our quality in this step:

- Textile finishing in Germany

- Latest technology that is gentle to fabrics and the environment

- Tubular finishing

- Centrefold through the centre of our sheets

Step 4: Making / sewing our fitted sheets

Our products are made in Germany or in our factory in the neighbouring region of Alsace. Recently, a family sewing business in Slovakia has also become one of our trusted partners.

The bale goods are laid out, cut, sewn, checked, folded and packed.

What defines our quality in this step:

- High-quality brand rubber for the elasticated border

- Strict approval criteria for seams and fabric surface quality

- Manual control of each and every single sheet

We choose not to outsource even the labour-intensive production step of sewing to low-wage countries.

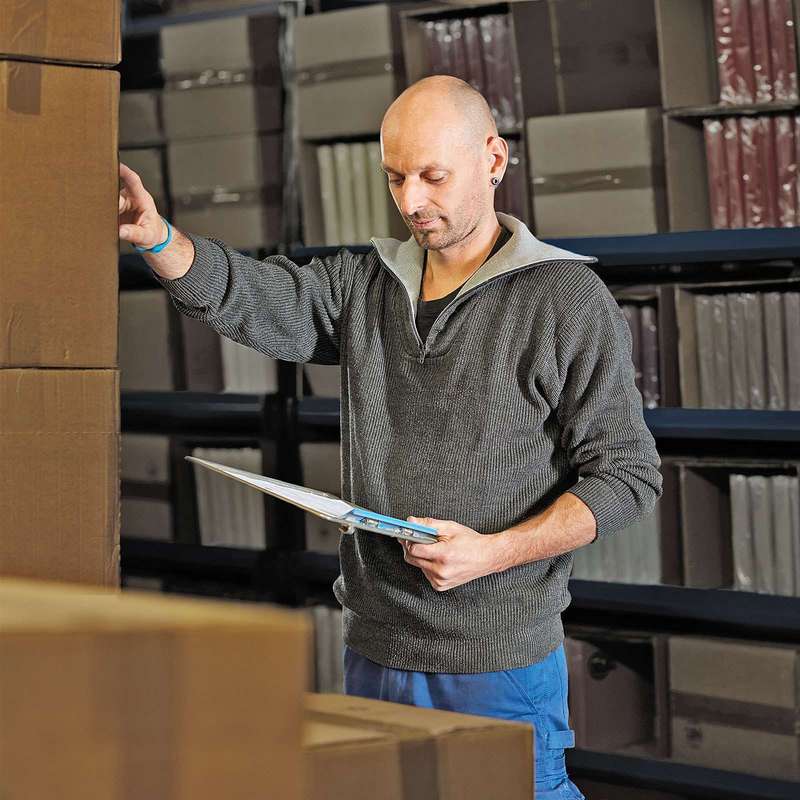

Step 5: Warehousing and dispatch from the Black Forest

Finally, our finished products are stored at our main warehouse in the German Black Forest and are dispatched from here. Our warehouse is so well stocked that we can deliver a whole range of different colours and sizes immediately.

In September 2016, a fire spread to our warehouse from a neighbouring property. This was extremely bad luck for us, but it could have been much worse. Nobody was hurt and we were able to save a lot of our stock. For the last two years, we have continued to operate our warehouse in a rather improvised manner while rebuilding the sections that were destroyed. We made the best of an unfortunate situation and have completely modernised our warehouse and equipped it with the latest software and hardware.

When can you say ‘Made in Germany’?

For the consumer, the ‘Made in Germany’ claim is a difficult one to assess. There is no clear legal proviso as to how many product components must actually come from Germany, or which part of the production process must take place in Germany for this quality seal to be awarded. However, we believe that this promise is one that must stand up in a court of law.

We trust we were able to explain our production process to you in a comprehensible and transparent way. And we hope we managed to convince you that our products fully deserve their ‘Made in Germany’ label.