The Formesse story

A very warm welcome to you all!

My name is Matthias Jaschke and I’m Managing Director of Formesse. It was my grandparents who first founded Formesse over 70 years ago.

Transparent and sustainable production conditions have become an important purchase criterion for increasing numbers of customers. I would like to show you how we produce our products and what’s so important to me about their production. Why we are all so proud of the products we sell. I very much hope you will sense something of that positive feeling when you use our products.

Your Matthias Jaschke

From work clothing to fitted sheets

At home in the Black Forest for over 70 years. And that’s not set to change.

It all began with work clothing. When my great-grandfather laid the foundation stone for our family business in Germany’s Black Forest, these were the first products he made. In 1947, his daughter, my grandmother, founded today’s company Formesse with her husband, producing bed linen and other trousseau textiles.

Fitted sheets become popular

My father took over the family business from my grandparents in the 1970s. Up until then, we had focused mainly on bed sheets made from woven fabrics and 100% cotton fitted sheets that really weren’t a perfect fit. My father was the one to introduce and develop stretchy fitted sheets as we know them today.

Formesse was amongst the first to develop fitted sheets with elastane, making a significant contribution to today’s market.

Entrepreneurial spirit and good luck

The Benelux countries are the pioneers of sleep culture. These countries have prized high-quality sleep products for a long time. In the mid 1980s, a Dutch friend and business partner encouraged my father to develop the perfect elasticated fitted sheet. In those days, waterbeds had just entered the market and were already much more widespread in the Benelux countries than in Germany. Our Dutch business partner was looking for a solution for these rather more complicated, mobile and thicker mattresses. The answer was Bella Donna Jersey.

The Benelux countries remain a key market for us today.

Bella Donna – the brand with the beautiful woman

Our Bella Donna brand has become somewhat of a household name and some may still recall the mysterious beauty, who once graced the front of our packaging. The same motif can still be found on the back of our packaging today. Although this beautiful woman looks as if she comes from the 1920s, she in fact dates back to the early 1990s.

But as we all know: true beauty is timeless.

As is quality.

Synonymous with premium quality

By the late 1990s, our specialist knowledge of high-quality elastane fitted sheets transformed Formesse into textile specialists. The world of waterbeds was now open to us. Because not many fitted sheets can stand up to the challenge of a moving mattress, yet still provide a wrinkle-free surface.

High-tech beds – the next challenge

The trend for boxspring beds and innovative bed systems with adjustable head and/or foot sections was the next challenge we were more than happy to tackle. Now we are proud to say: We have exceptionally good fitted sheets for all types of beds and mattresses.

The Formesse name stands for high-quality, long-lasting fitted sheets that fit your mattress perfectly without a wrinkle – even the next morning.

We now offer more than fitted sheets

Although the core focus of our company remains on the production of fitted sheets, we also have to mention our wonderful pillowcases, useful protective covers and stunning summer blankets. All of these products have been added step by step to our range and we sell them with complete conviction. Because when it comes to quality and function, they’re certainly on a par with our fitted sheets.

….and so the story continues.

Our values and philosophy

The priorities of a family business

We are a third-generation family business. Which means we set rather different priorities and goals to many other companies.

Many of our employees and partners have worked with us for years, some even for decades. Their experience makes an irreplaceable contribution to the success of our company. We have flat hierarchies and treat each other with respect and well-earned trust. This form of togetherness and keeping an eye on generations to come are very important for us to continue forging a healthy and sustainable path in future.

Quality from conviction

The values of the Black Forest are deeply engrained in our company culture: an appreciation of quality, care for the environment and fair dealings with our employees, our customers and our suppliers.

Innovative technologies and efficient production and sales structures are deeply embedded in this set of values. Almost our entire production is located in Germany and in the neighbouring region of Alsace. And recently, a family business in Slovakia has become one of our trusted partners. This close proximity to one another, both culturally and geographically, and our trusted partnerships are what enable us to manufacture such high-quality products.

Our products mirror our company philosophy in their exceptionally high, long-lasting and immediately tangible quality.

Made in Germany

As a fully developed industrial country, Germany sets exacting social, industrial health and safety, and environmental standards, to name but a few. Many textile companies outsource their production to less developed countries to save money. However, we believe these standards to be an important achievement. They drive us to better management and greater efficiency using the latest technologies. We can’t compete with low-cost manufacturers – that much is clear. However that is not our intention.

Our products speak for themselves: exceptional quality at a fair price.

Our responsibility

Our products and the environment

We believe conscious consumption to be the answer to many of the challenges of our time. Which is why we are proud to produce our products in Germany in accordance with strict environmental standards. Products of such high quality, they can be used for years to come.

We implement the European Chemicals Regulation REACH in all our products. Moreover, our products are checked and certified according to STANDARD 100 by OEKO-TEX®.

We use FSC-certified product inserts and are currently in the process of testing new packaging made from grass. Naturally, our product packaging is fully recyclable.

Climate-neutral production

The entire production process for our summer blankets and summer pillowcases is now carbon neutral since 2019. Carbon emissions were calculated by ClimatePartner Deutschland GmbH and carbon offset payments are sent to an internationally recognised forest protection project in Portel, Brazil. We chose this particular project because of the country’s current political situation and the associated move away from rainforest and environmental protection.

Our selected shipping service DPD also commits to carbon-neutral parcel delivery.

Sustainable raw materials: Lyocell, organic cotton and more

We have used the fantastic sustainable fibre TENCEL™ Lyocell from Lenzing in some of our products for many years now. Lyocell is derived from the renewable raw material wood and is fully biodegradable. In the particularly environmentally friendly Lyocell production process at Lenzing, the organic solvent NMMO is used to break down the wood pulp. Moreover, the recovery rate of this very valuable chemical with Lenzing technology is over 99%. Moreover, Lenzing only uses wood from sustainable forest management. We use Lyocell for our summer blankets and summer pillowcases, as well as our Bella Donna Clima and Satinesse AIR protective covers.

We source our high-quality cotton yarns from a small circle of selected German yarn dealers. We have been looking into organic cotton for many years, but still have a few hurdles to overcome. Our products require very high-quality, long-staple cotton and premium qualities of single and ply yarn. The organic cotton market still struggles to guarantee a regular and reliable supply of these commodities. A fact that is reflected in price, because scarce commodities become expensive. In our case up to 15% more expensive. We are working at making our processes even more efficient and modern, which would allow us to absorb these additional costs. Our aim is to switch to using organic cotton in the medium term.

We always keep an eye out for other sustainable raw materials that are currently being developed or rediscovered, as well as testing exciting ideas and innovations ourselves.

Environmental protection in office life

We make every effort to be as environmentally friendly as possible in our office life. Wherever possible, we buy high-quality, sustainable products that are made in Germany. We introduced paperless billing a few years ago. We make carbon offset payments for our company cars. We switched to clean electricity from a local energy provider in 2018 and heat with local heat from Stadtwerke Löffingen. In 2006, we equipped our warehouse rooves and a large outdoor area with solar panels. We make every effort – although we have to admit that changing human behaviour isn’t easy! But we’re working on it and are happy to say we’re becoming better all the time.

Our solar panels produce electricity for approx. 56 four-person households or 76 two-person households.

Blooming Nature Park Southern Black Forest

We support the ‘Blooming Nature Park Southern Black Forest’ project and have landscaped the green area around our company to be a flowering one that is insect and animal-friendly. We let natural hedges grow, provide natural shelters for small animals and nesting boxes for birds, streams and small ponds. We have also let our fields flower naturally and support the growth of indigenous, insect-friendly plants through the use of site-specific seed mixtures.

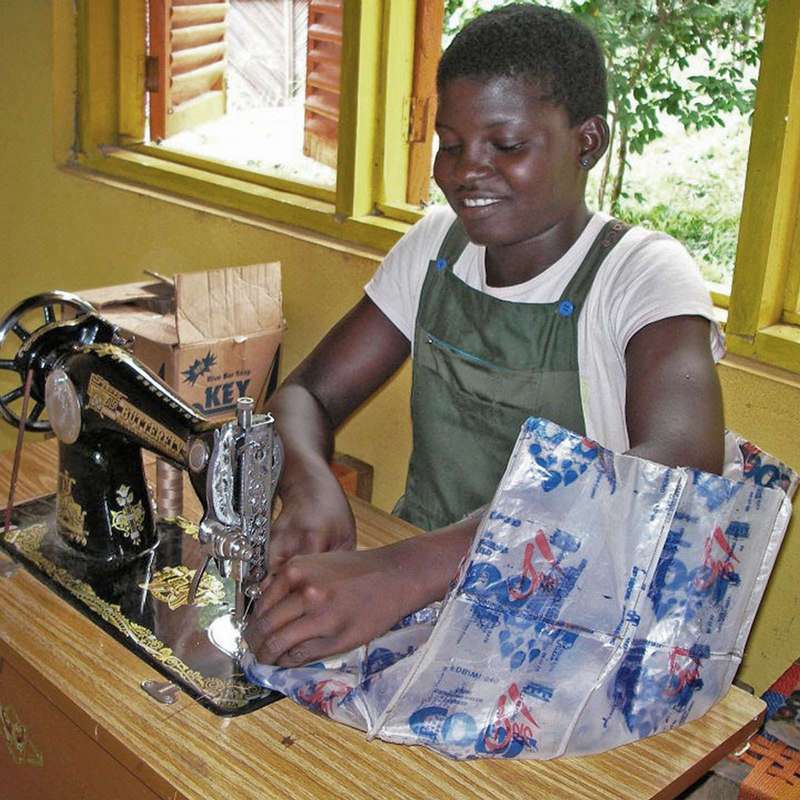

Social commitment from the Black Forest to Ghana

We contribute to smaller and larger charity projects – both locally in the Black Forest and worldwide. These include regional projects such as the Lynx Initiative Baden-Württemberg e.V. and the homeless refuge[RAG1] Schlupfloch run by Caritas in Titisee-Neustadt, but also national and international organisations such as the German Red Cross, Doctors Without Borders and Welthungerhilfe.

We have supported the Baobab Children Foundation in Ghana since 2010. The foundation takes in street children and children of school age who are too poor to attend school in Ghana. At Baobab, these young people learn to read and write, are taught mathematics and English, and are also equipped with practical vocational skills.

Moreover, we donate fabrics and fitted sheets to welfare organisations. We regularly support the charity innatura, which operates Germany’s first platform for distributing brand-new material donations to charitable organisations on a needs-oriented basis.